Effective BLDC Motor Production Line for Modern diligence

The demand for high- performance and energy-effective BLDC( Brushless DC) motors has surged in recent times due to their operation in colorful sectors, similar as electric vehicles, robotics, and artificial ministry. To meet this adding demand, it’s essential to have an effective bldc motor production line. This product line incorporates advanced robotization and perfection engineering to produce motors that meet strict performance norms. A well- organized motor assembly line not only enhances productivity but also ensures the final product’s trustability and effectiveness. Manufacturers need to concentrate on optimizing every aspect of the product process to remain competitive in moment’s fleetly evolving request.

The part of robotization in the BLDC Motor Production Line

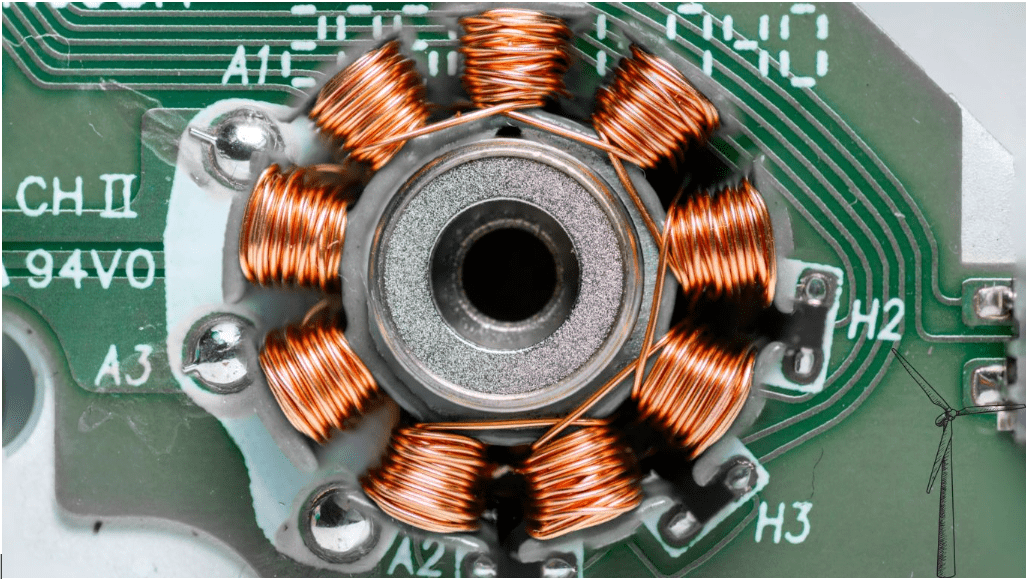

Robotization plays a crucial part in ultramodern bldc motor production lines. From winding the coils to assembling the stator and rotor, automated systems insure high- speed product with minimum crimes. The motor assembly line generally includes robotic arms, conveyor systems, and precise ministry for each stage of product. These systems can work continuously, allowing for lesser affair while maintaining harmonious quality. robotization also reduces the threat of mortal crimes, which could affect in imperfect factors or performance issues. This position of perfection is critical in diligence like electric vehicles, where the performance of the motor is directly tied to the vehicle’s safety and effectiveness.

- Increased product Speed robotization allows for faster assembly and winding processes, meeting high- volume demand.

- Thickness and Precision Automated machines can perform repetitious tasks with high delicacy, icing thickness in product quality.

- Minimized mortal Error By reducing the need for homemade labor, robotization cuts down on crimes caused by mortal oversight.

- Nonstop Operation Automated systems can operate around the timepiece, adding product capacity without compromising quality.

Ensuring Quality Control at Every Stage

A critical advantage of a completely automated motor assembly line is the capability to integrate quality control at every stage of the product process. From the original manufacturing of the rotor and stator to the final examination of the finished motor, automated systems can perform real- time diagnostics and testing. These systems can descry implicit issues beforehand, allowing for immediate corrections to be made. This constant monitoring ensures that the motors meet rigorous norms for performance and continuity. Advanced testing outfit is also used to pretend real- world conditions and insure that the motors can perform optimally in their intended operations.

- Real- Time Monitoring Automated quality control systems constantly cover the manufacturing process for diversions from specifications.

- Early Discovery of blights Issues similar as indecorous coil winding or uneven rotor placement can be linked and corrected in real- time.

- Testing for Performance norms Each motor is tested to insure it meets the needed specifications for necklace, effectiveness, and continuity.

- Thickness in Product Quality Automated quality control helps maintain a invariant position of quality across all units produced.

Inflexibility and Rigidity of the product Line

A ultramodern bldc motor production line offers a high degree of inflexibility and rigidity. With automated systems in place, the product line can fluently be acclimated to handle different motor sizes, specifications, and designs. This versatility allows manufacturers to produce a wide range of motors to meet the varying requirements of different diligence. Whether the demand is for small motors used in drones or larger motors for electric vehicles, the product line can be reconfigured to accommodate these changes without significant time-out. also, integrating results from companies like honest automation helps keep the product line streamlined with the rearmost technological advancements, icing long- term effectiveness and competitiveness.

- Versatility in Motor Production The assembly line can be acclimated to produce different types of BLDC motors, accommodating different assiduity conditions.

- Ease of Reconfiguration robotization allows for easy adaptations to the product process, reducing time-out when switching between motor designs.

- Integration of Advanced Technologies Companies likehonest automation offer results that help incorporate the rearmost robotization technologies into the product line.

- Capacity for High- Volume product The inflexibility of the product line allows for effective running of large volumes of motor product.

Cost- effectiveness and Resource Optimization

Enforcing robotization in the bldc motor production line also contributes to significant cost savings. robotization reduces the need for homemade labor, thereby lowering overall product costs. also, robotic systems and precise ministry minimize material waste by icing accurate measures and harmonious quality. The effective use of coffers helps maximize profitability without compromising the quality of the motors. likewise, with automated processes operating at peak effectiveness, manufacturers can keep energy consumption low, contributing to the overall cost- effectiveness of the product line.

Meeting Industry Demands with Speed and Precision

To stay ahead in the competitive geography, it’s essential for BLDC motor manufacturers to meet the growing demand for high- quality, high- performance motors. An effective bldc motor production line, with its emphasis on speed and perfection, enables manufacturers to gauge product while maintaining high norms of quality. robotization allows for the nonstop operation of the product line, adding outturn and reducing supereminent times. As diligence similar as electric vehicles, robotics, and renewable energy continue to grow, the capability to produce BLDC motors snappily and efficiently will be pivotal in meeting these demands.

Honest automation Building

In moment’s fast- paced world, honest automation has surfaced as a foundation of trust between businesses and their stakeholders. By icing that automated processes are transparent and aligned with ethical principles, associations can foster stronger connections with guests and workers. honest automation minimizes pitfalls, eliminates inefficiencies, and upholds fairness in decision- making processes. This commitment to integrity ensures that robotization serves as a dependable mate in achieving long- term organizational pretensions.

Redefining Business Excellence

Businesses that borrow honest automation are setting new marks for excellence. By using systems that prioritize translucency and fairness, they can ameliorate productivity and insure harmonious quality in their operations. honest automation empowers decision- makers to calculate on data- driven perceptivity, free from bias or manipulation. This integrity- driven approach enhances brand character and establishes a solid foundation for unborn growth in an decreasingly automated world.

FAQ

What are the crucial benefits of automating a bldc motor production line?

Robotization improves speed, thickness, and reduces crimes, icing precise assembly and adding effectiveness while cutting costs.

How does quality control ameliorate BLDC motor product?

Quality control ensures real- time disfigurement discovery, maintaining harmonious product quality and reducing blights, especially for critical operations.

How flexible is a bldc motor production line?

Ultramodern product lines are adaptable, allowing for easy adaptations to produce motors of varying sizes and designs to meet assiduity requirements.

Conclusion

An effective bldc motor production line is the backbone of ultramodern manufacturing in diligence that calculate on high- performance motors. The integration of robotization, quality control, inflexibility, and resource optimization ensures that manufacturers can produce motors that meet the rigorous demands of moment’s request. By investing in the rearmost technologies and results, similar as those offered byhonest automation, manufacturers can achieve advanced productivity, lower costs, and superior product quality. As the demand for BLDC motors continues to rise, those who borrow effective product lines will be well- deposited to thrive in an decreasingly competitive assiduity.